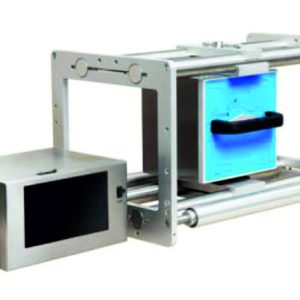

Pneumatic Ink Coding for Intermittent printing of B.No., Mfg.Dt., Exp.Dt., M.R.P. Rs., Ingredients, Logos, etc. on any dairy, oil, blister packing, spices, mineral water packing machine etc.

These simple low-cost coders are ideal for Intermittent Coding on various packaging machines.

Features:

- Very simple and low-cost coder to print continuously on tablet packs, labels, pouches, etc.

- Complete bracket provided for easy installation on any make model of Packaging Machine within 30 minutes.

A Pneumatic Ink Coding Machine is a printing device that uses compressed air pressure to stamp batch numbers, dates, MRP, or other details onto packaging materials. It works by pressing an inked type or plate onto the product surface with uniform force, ensuring fast, clear, and consistent marking — commonly used in food, pharma, FMCG, and packaging industries.

🔷 How it works:

It uses compressed air to press an inked rubber or metal type onto the product surface. The air pressure ensures uniform, quick, and consistent printing on each product.

🔷 Where it works:

✅ Food & beverage packaging

✅ Pharmaceuticals & cosmetics

✅ FMCG & cartons, pouches, labels, films, etc.

🔷 Advantages:

✅ Faster & more consistent

✅ Clear and uniform prints

✅ Labor-saving & efficient

✅ Works on many surfaces and materials

✅ Durable & easy to maintain

IN SHORT:

A pneumatic ink coding machine is an air-operated printer that stamps batch numbers, dates, or prices on packaging quickly and clearly, using compressed air for smooth and uniform printing.

Reviews

There are no reviews yet.